Welcome to Printera

Your premier destination for high-quality, precision 3D printing solutions. At Printera, we specialize in turning your visions into tangible reality through cutting-edge concrete 3D printing technology. Our services range from land to sea, all crafted with unparalleled expertise and attention to detail. Whether you’re an Architect seeking to create unique structures or a construction professional in need of custom components, our dedicated team is committed to delivering exceptional results. Discover how Printera can bring your concepts to life with durable, innovative, and meticulously crafted concrete 3D prints.

Why Choose Us

Printera is a specialized building material manufacturer. We use robotic 3D concrete printing to fabricate custom architectural and landscape components that would be prohibitively expensive using traditional formwork.

Unlike on-site 3D printing services, we manufacture everything in our climate-controlled facility in Stuart, Florida. This "Pre-Printed" approach gives us complete quality control and eliminates weather delays. We deliver finished components to your project site, where your contractor installs them.

Pre-Printed 3DCP On-Site 3DCP

20 min Startup

Controlled Conditions

Crew of 1-3 People

Full Size Range Capabilities

Quality Control in Every Layer

Parallel Production During Site Prep

Acts as Material Supplier

Your Contractor Installs

+2 Days for Setup / Breakdown

Weather Delays

Crew of 5-9 People

Limited by Size of Printer

Variable Site Conditions

Requires Site Access

Acts as Temporary Contractor

Print Crew Installs Walls Only

Pre-Printed Results: Predicatable Quality - Faster Timelines - Lower Total Cost

Pre-Printed 3DCP

Printera revolutionizes 3D concrete construction by moving the printer off-site and bringing precision indoors. Unlike traditional on-site 3DCP, which battles unpredictable weather and requires days of setup, our pre-printed method utilizes a strictly controlled facility where material, water, and ambient temperatures are perfectly regulated. Supported by a 17-sensor monitoring system, we guarantee superior quality that variable site conditions simply cannot match. We act as your material supplier rather than a competing contractor, allowing you to run site prep in parallel while we produce flawless components that are delivered ready for your team to install—saving you days of labor and logistical headaches.

An Award-Winning Concrete 3D Printing Firm

PRINTERA is a leading innovator in the use of 3D-printed concrete technology in Florida. With a mission to revolutionize the concrete industry, we have developed a unique process that allows for faster, more efficient and environmentally friendly building processes. Our unique approach to printing indoors and having parts delivered to the job site allows for more precision, cost savings and faster lead times. Our team brings together expertise in designs, architecture, landscape, engineering, and construction, enabling PRINTERA to provide a holistic approach to all of our client projects.

15-30% Cost Savings

2-3 Week Turnaround

70% Less Waste

Code Compliant Products

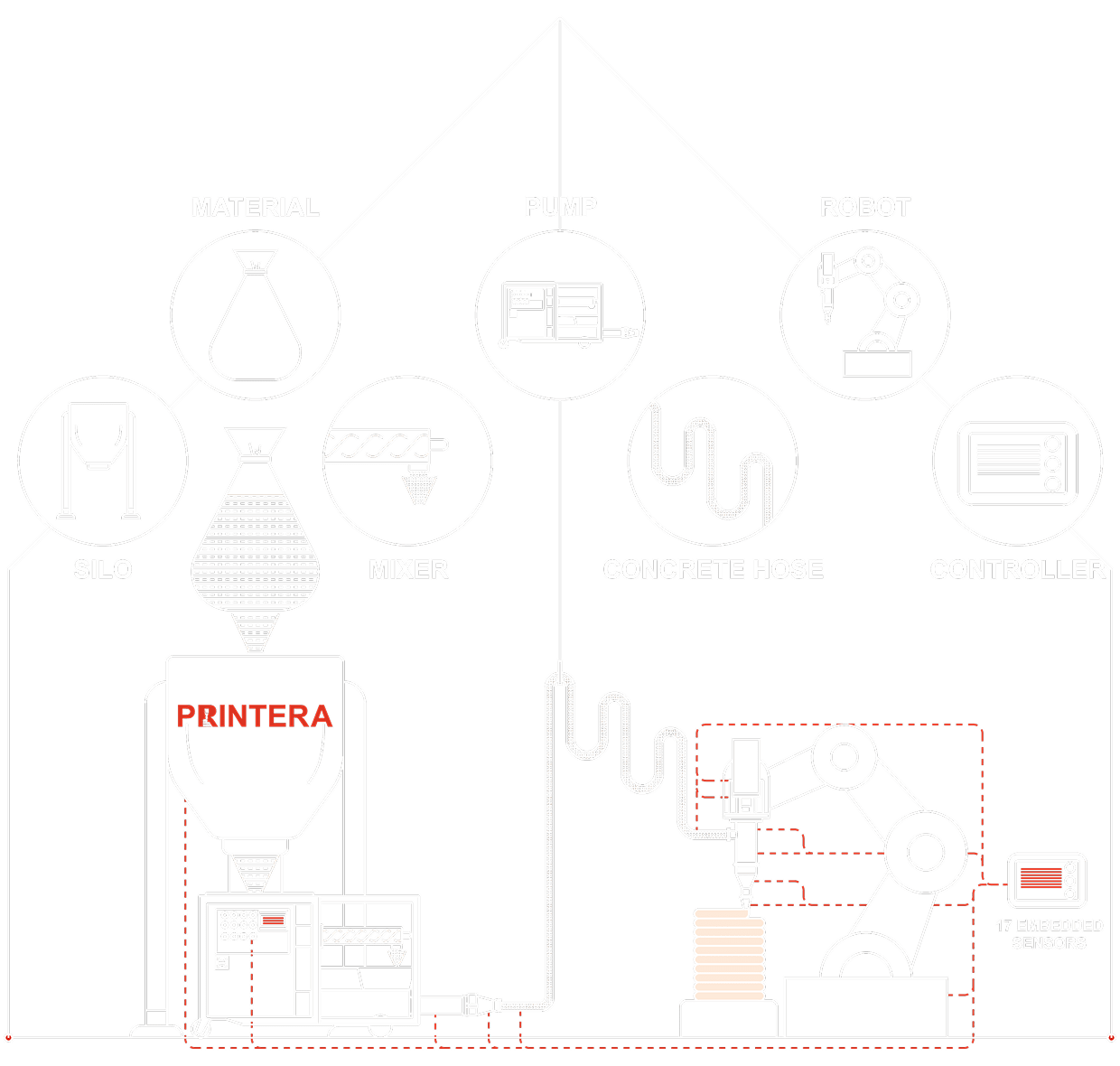

The Process

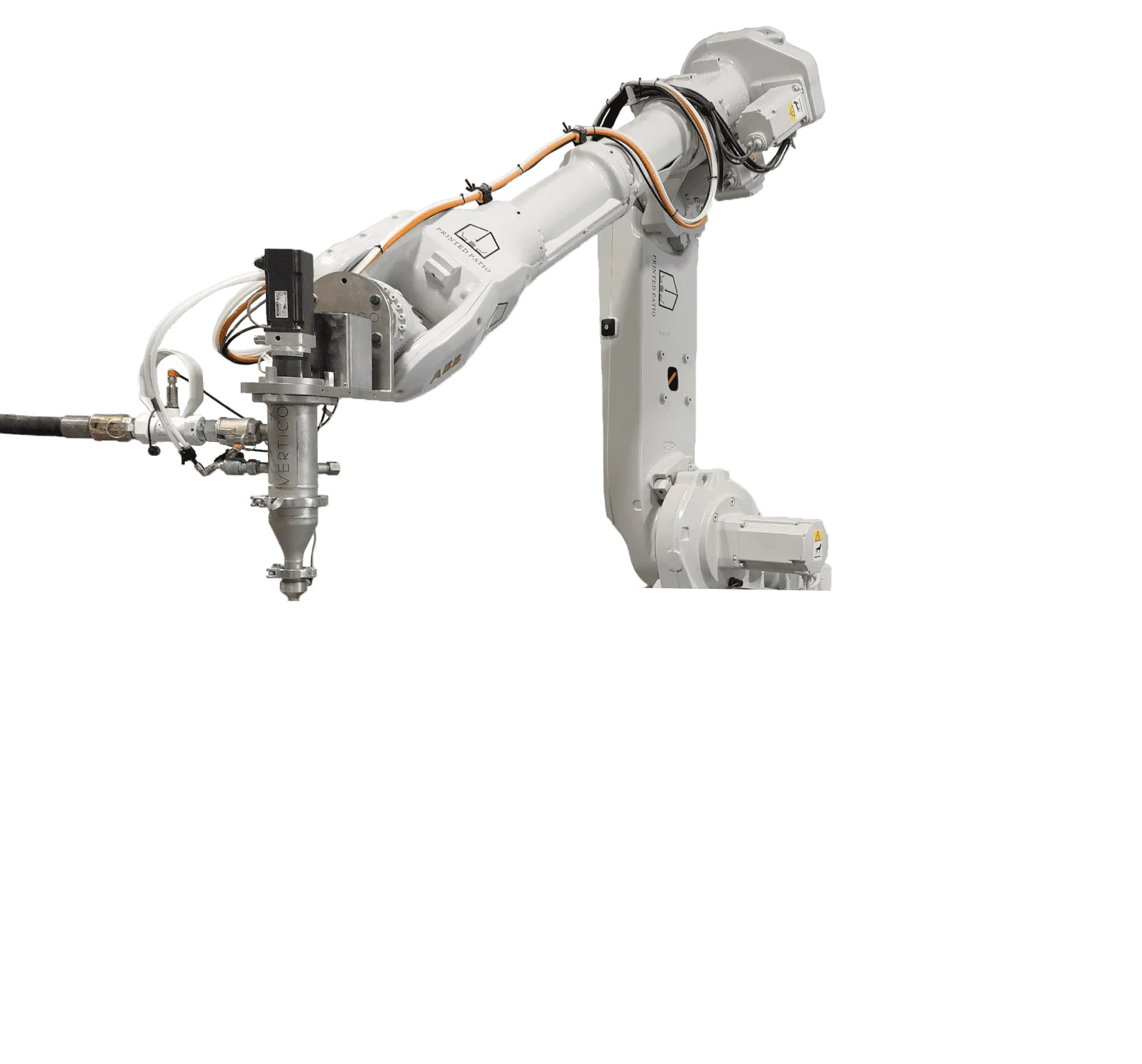

Our 3D concrete printing process begins with a digital design—a 3D model created using CAD software. Once finalized, the design is loaded into our robotic arm printer, which extrudes concrete layer by layer, precisely following the digital blueprint. This automated process allows for complex geometries, minimal material waste, and significantly faster production than traditional methods.

What truly sets us apart is not just our exceptional layer quality, but the way we operate. Unlike most in the industry, all of our printing is done indoors at our controlled facility. This means better quality control, zero weather delays, and a cleaner, more efficient process from start to finish.

-

Design

-

Pre-Printed 3DCP

-

Allow to Cure

-

Package

-

Deliver

-

Ready for you to Install

Printera run an extremely professional facility. The Pine School enjoyed working with the entire team and deeply appreciated the attention to detail throughout the creative process. Both the benches and planters add a unique touch to our School front entrance.

Robert A.

The people at Printera were spectacular, they did exactly what I was looking for and designed it perfectly, came out amazing

Joseph B.

Justin and Justin were great to work with and made it very easy for us. Designed, delivered and installed. Excellent service and a fantastic product. We will be doing additional business with the guys.

Robert R.

Amazing product and truly a wonderful buying experience. Justin, the owner, was there every step of the way - from design to delivery, including photos all through the construction phase. Very thoughtful. Our bench and planters are spectacular.

Martin S.

These guys are the best check out this anything from flower planters to houses they have you covered.

Donald C.

Meet 3D-CPO

My journey from automotive robotics to the forefront of 3D concrete printing has been a remarkable odyssey—a transition from one expertise to another, a testament to adaptability and the pursuit of innovation. As I print the future, I remain deeply honored to be part of Printera's legacy, bridging continents to redefine the very fabric of construction methodologies.

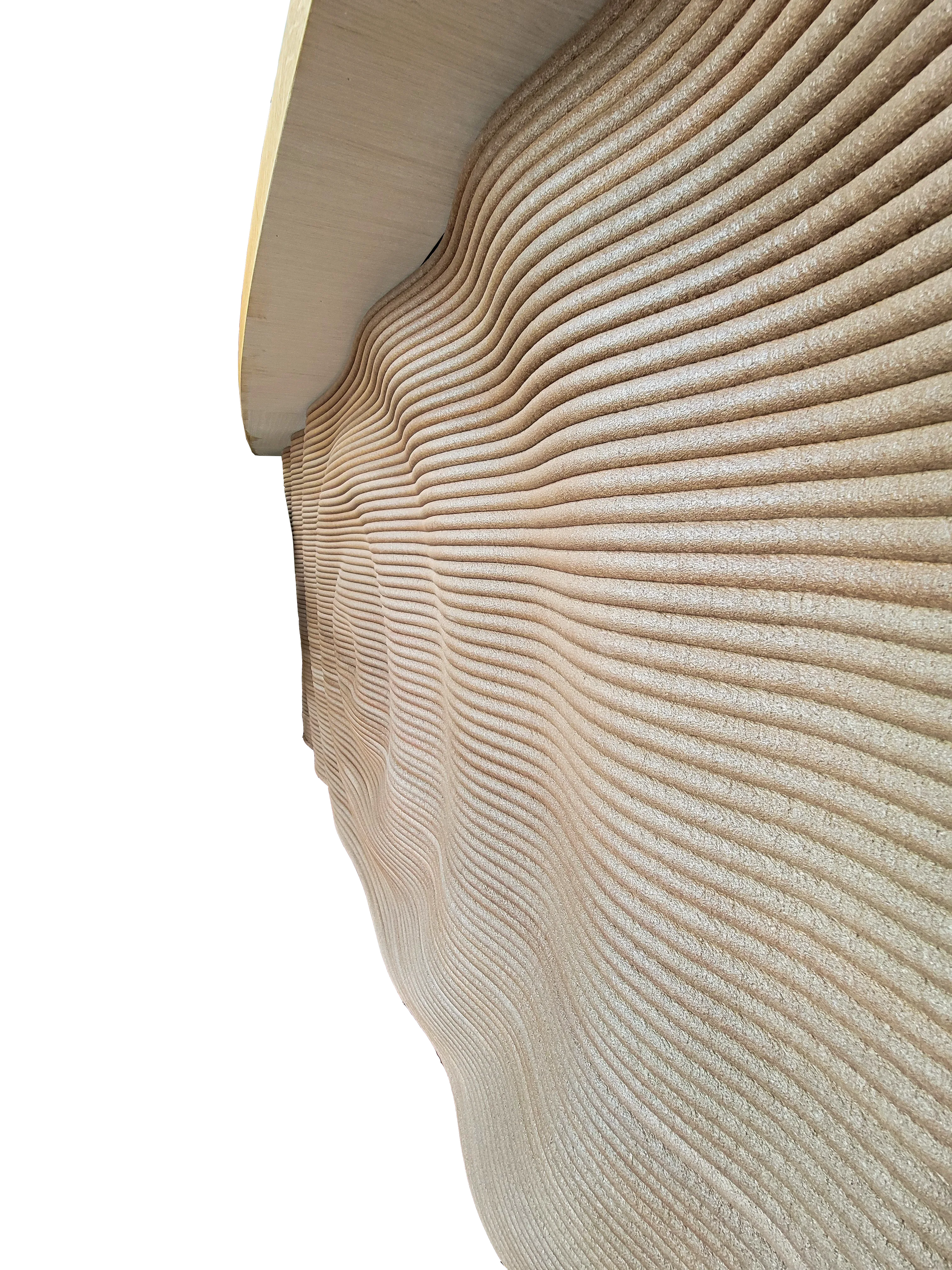

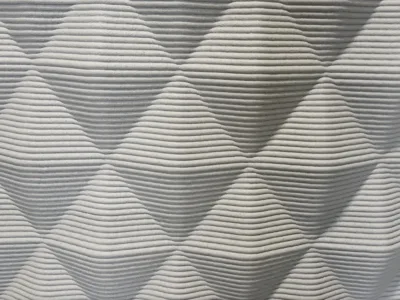

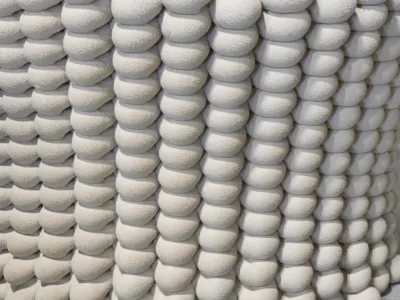

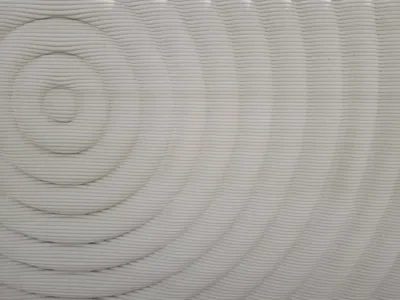

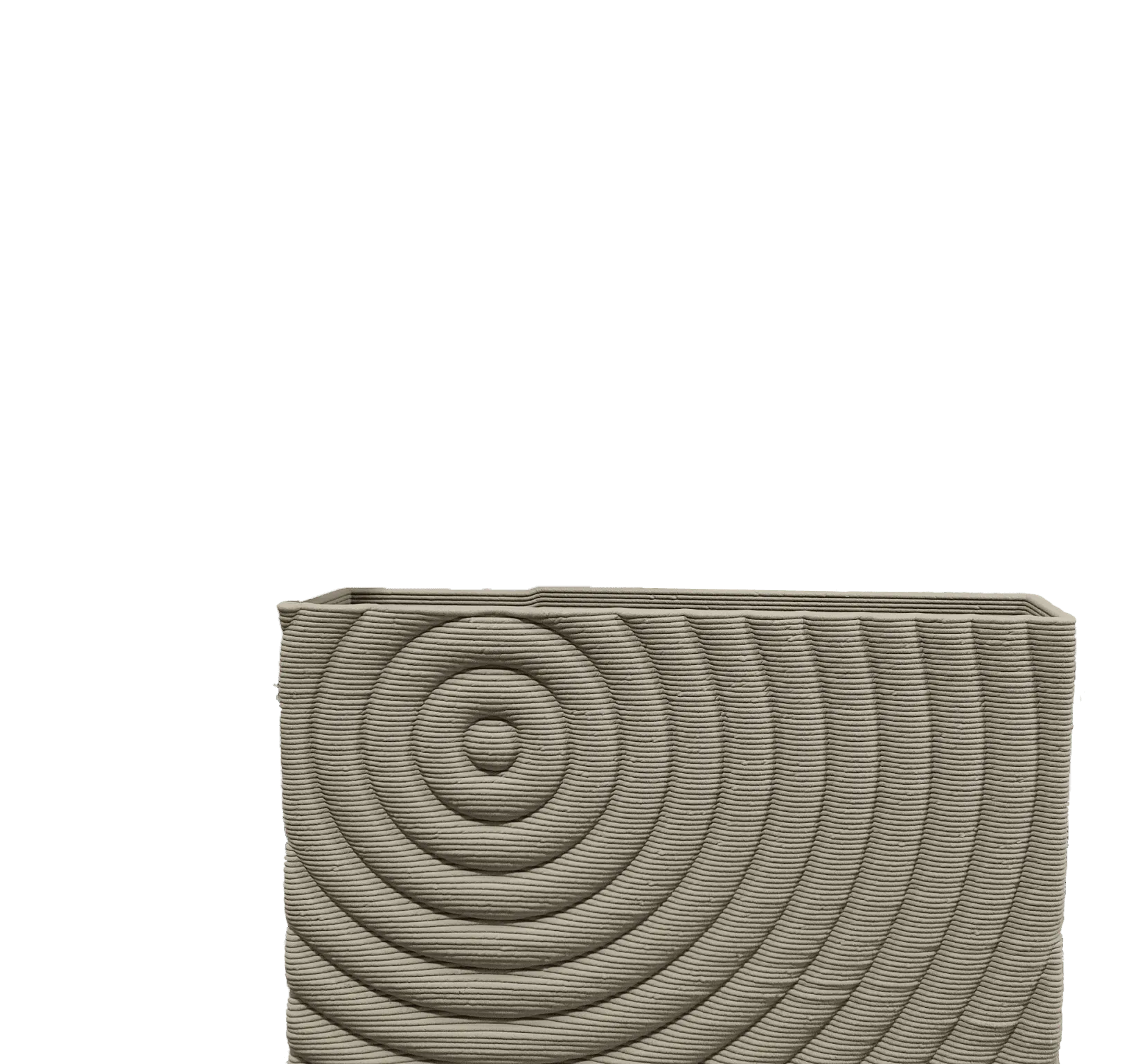

Customize Your Project

To add uniqueness to your creation, consider incorporating patterns, textures, or intricate details. This can be done by selecting one of our preset patterns or contacting us to create a custom pattern for your project.

Select a Base Shape

Customize Size

Add Pattern

Select Color (optional)