3D Printed Reefs Built to Restore:

Printera’s Latest Drop at the Florida Oceanographic Center

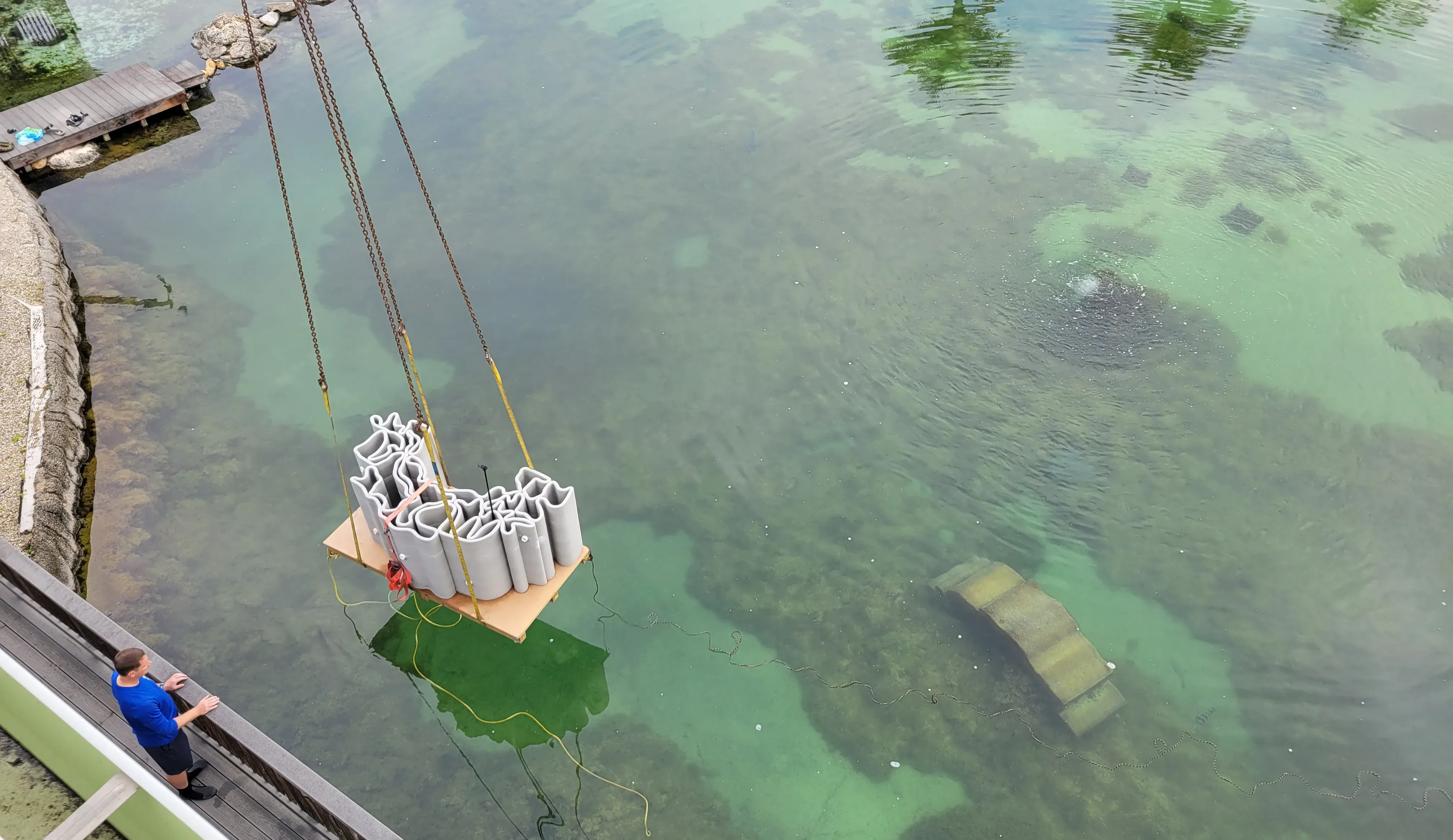

Concrete 3D printing isn’t just reshaping how we build structures, it’s also helping to restore the environments that surround them. In a recent partnership with the Florida Oceanographic Center in Stuart, Printera delivered two large-scale concrete 3D printed reef structures designed to support marine life and promote recovery for injured sea turtles.

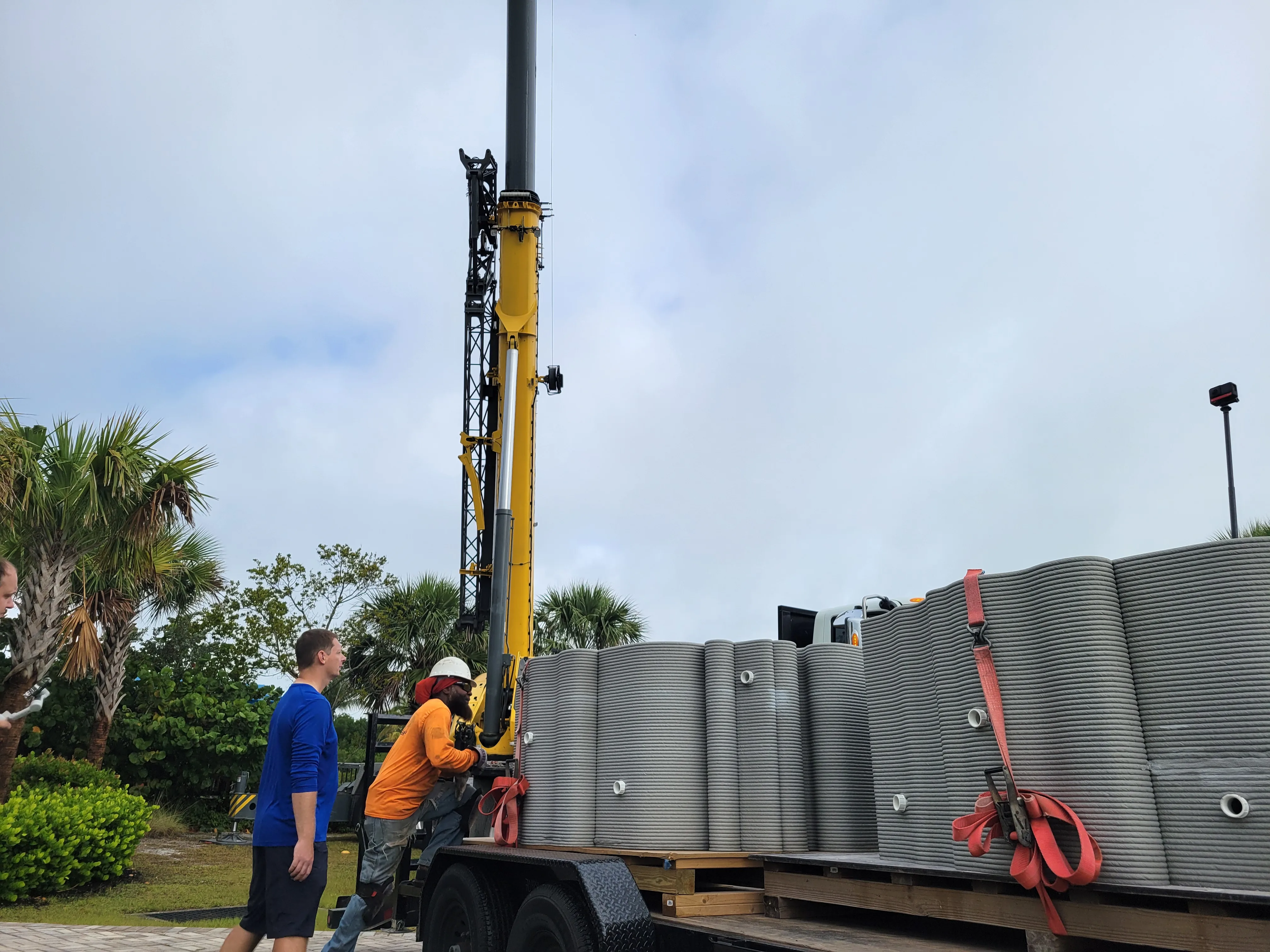

Each reef was 3D printed at Printera’s facility using our Pre-Printed method and a durable, domestically sourced concrete mix. The fabrication process for each piece took less than two and a half hours and cost approximately $4,000. This demonstrates how 3D concrete printing can offer scalable, cost-effective solutions, and customization for environmental restoration.

Engineered for Aquatic Life

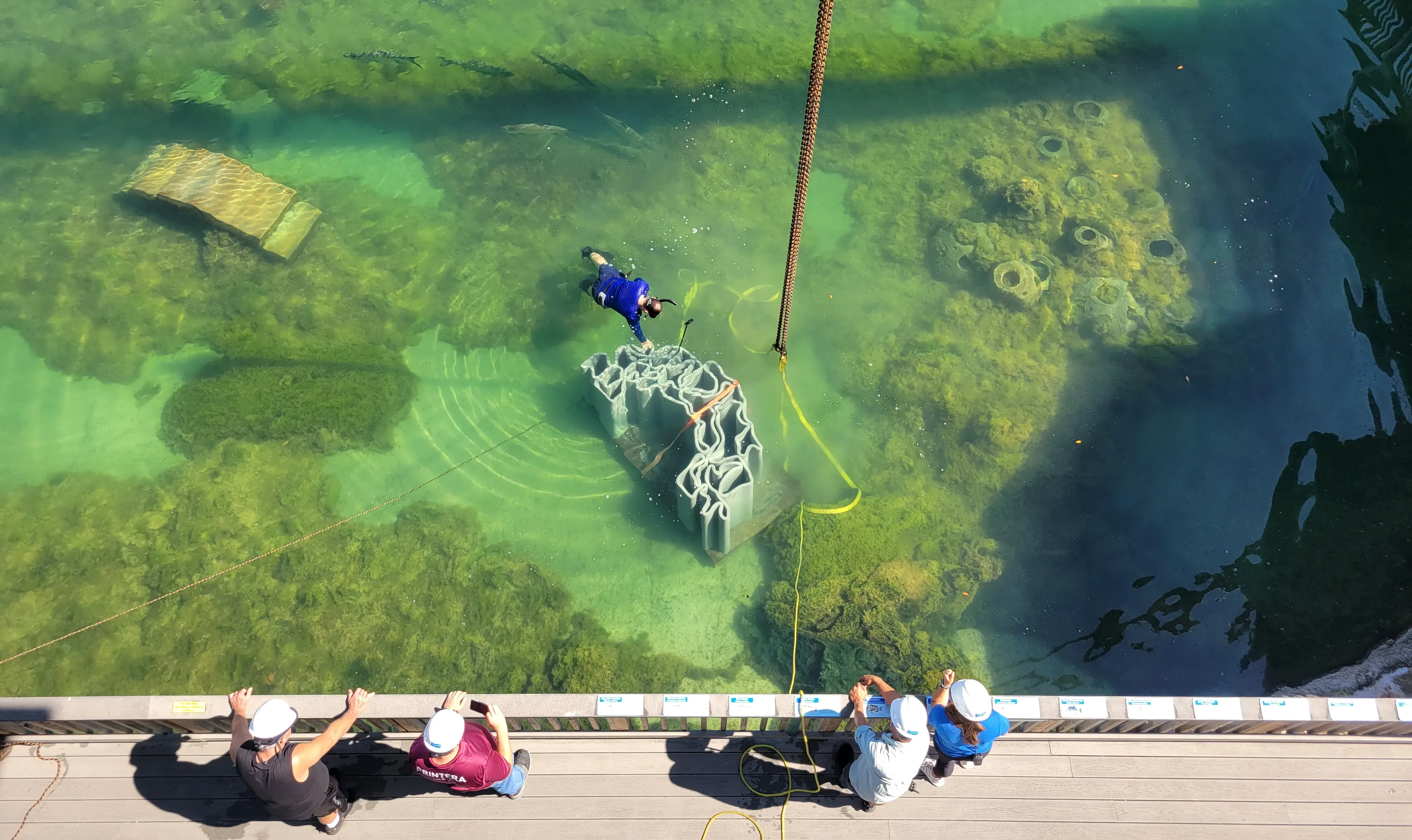

The reef design incorporates arches and internal cavities that allow fish to pass through, rest within, or explore the structure from multiple angles. These varied pathways help mimic the complexity of natural reef systems and encourage engagement from both small and large marine species.

At the top of each reef, integrated PVC inserts allow for the future placement of coral or other enrichment features. This makes the reef not only a shelter, but a potential base for new marine growth.

These structures are already in use at the Florida Oceanographic Center’s Gamefish Lagoon, where they’re being integrated into the habitat as both enrichment and rehabilitation tools. For sea turtles recovering in the lagoon, the reefs provide natural resting surfaces closer to the bottom, supporting their mobility and mimicking real-world behavior.

A Project Two Years in the Making

Printera began exploring artificial reef design in 2022, with early prototypes created under their previous company name. Since then, Printera has refined both the printing techniques and the material composition. The result is faster prints, stronger structures, and a fully U.S.-sourced mix that improves both performance and supply chain reliability.

This recent installation reflects the next step in that evolution. It offers a more efficient, adaptable version of the original reef concept while keeping environmental impact and function at the forefront.

Looking Toward Coastal Adaptation

While these reefs were created for a controlled lagoon environment, the technology isn’t limited to large-scale deployments. Similar structures could be adapted for smaller, site-specific needs, such as promoting biodiversity beneath residential docks or creating habitat pockets along seawalls.

We’re also continuing discussions around open-water use, where printed reefs could help mitigate habitat loss on a larger scale.

Building Beyond the Shoreline

At Printera, we’re proud to contribute to projects that demonstrate how concrete design and sustainability can work hand in hand. With the flexibility of 3D printing, we’re not only expanding what’s possible in architecture and infrastructure, we’re extending those possibilities into the natural world.

Want to talk about your next project? Let’s connect. Explore more examples of our work in our project gallery.